Quick Wins in the Battle for Higher Energy Availability

Quick Wins in the Battle for Higher Energy Availability

- Last Updated: December 2, 2024

Algo Engines

- Last Updated: December 2, 2024

The wind energy market is undergoing a transition across the world. Feed-in tariffs are being replaced by auctions, squeezing operating margins. The change is forcing asset owners to look at new ways of maximizing returns. While predictive maintenance, farm level optimization, vortex generators, and a range of new options are on the table, there are simple, low hanging fruits which often go unnoticed. A rigorous review of turbine data reveals simpler ways to prevent energy grid loss and improve availability, which are often ignored.

3 Steps to Prevent Energy Grid Loss and Improve Availability

We at Algo Engines have worked with a diverse fleet of wind turbines covering Original Equipment Manufacturers (OEMs) such as Gamesa, Vestas, GE, Suzlon, and Enercon. Based on our experience across 4 GW of assets, we wanted to list some of the low hanging fruits in the battle for higher availability and enhanced production. These are:

- Short duration alarms/restarts

- Performance issues

- Availability calculation

1. Short Duration Alarms

Alarms raised by turbines usually result in stoppage. However, many OEM systems allow alarms to auto reset, which will result in turbines restarting instantaneously. The resets fall under multiple categories:

- Automatic resets SCADA/Operator resets

- Remote resets

- Local/turbine resets

Many alarms allow up to three automatic resets, however, during an automatic reset the turbine will stop and start or pause. This stop-start or pause process usually takes 5-15 minutes depending on the OEM. One good questions to ask is: who pays for the loss due to this restart?

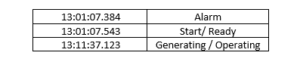

Notice that we mentioned three automatic resets. This process could happen multiple times a day. A turbine in which these resets occur often is considered "available" as the reset is instantaneous. A study of the log will reveal that the turbine was down for less than a second (see the example below.) However, it will take the turbine a while to move back into its generating mode, thereby affecting production.

Image Credit: Algo Engines

We identified cases in which the turbine did not generate for over 20 hours in a three month period due to one auto re-settable alarm: drive-train dampening. We could also locate cases involving other alarms related to synchronization delay, which caused the turbine to move into a stop-start or pause mode: a sizable energy loss in production that usually goes unnoticed. There may be no quick fix solution to prevent energy grid loss. However, correctly accounting for energy and time lost due to short duration alarms will help create a clear picture of availability and energy losses.

2. Performance Issues

A quick way to identify under-performance in a turbine is to compare the nacelle wind speed-based power curve to the one provided by the manufacturer. The under-performing turbine can then be assessed further. However, there can be a few complications in this approach. The OEM often comes back with a range of points including:

- Nacelle anemometer is impacted by blade movement and hence the speed isn't reliable

- Site conditions, turbulence intensity etc. aren't considered in this assessment

The discussion of the above points is never ending and the nacelle transfer function methodology is still not fully accepted. We've seen some simple tests that can result in identifying performance issues using this method. A late start is one such case. We've noticed that even though the wind speed is above cut-in, the turbine doesn't start immediately for 10 to 30 minutes.

Understanding that the energy lost in such cases can be immense, we recommend using notifications like the late start notification. The notification is generated only when conditions such as turbine status are OK and when the wind speed is above cut-in. These notifications help our customers take up such matters with the O&M and OEM for further investigation. Timely action ensures higher generation from individual assets.

3. Availability Calculation

Most of the wind asset owners have contracts with O&M / OEM for resources, machine, and/or energy availability. As usual, contracts are never the same, with a range of exclusions and inclusions. Implementing these contracts effectively is critical to validate losses and damages. We note many clients aren't convinced with the availability numbers provided by OEMs. There is a constant need to update the numbers provided. Here are a few simple cases with which we have experience:

In a case where availability was considered only when wind speed is greater than cut-in, we noticed cases in which turbines recorded wind speeds that reduce when the turbine is down or under alarm. A comparison of wind speed measurements with those of adjoining turbine’s indicated anomalous behavior.

A data loss or communication error appears when the turbine is down or under alarm and the OEM's system assumes the turbine is available when communication has in fact been lost.

There were also instances in which short duration alarms (less than 10 minutes) were ignored in availability computation. All these instances resulted in higher asset availability. With our analysis, the customer raised the issue with the OEM, who made changes in availability calculations. An asset owner can manually analyze such instances by investigating the SCADA logs' alarm data for one-off instances. However, as the asset capacity increases, this entire activity can become exhaustive.

By leveraging short duration alarms, performance analysis, and availability calculation, customers can get an accurate picture of their turbine availability and performance and identify where they can make quick and easy improvements. To prevent energy grid loss requires cunning strategy and a tactical use of energy technology.

The Most Comprehensive IoT Newsletter for Enterprises

Showcasing the highest-quality content, resources, news, and insights from the world of the Internet of Things. Subscribe to remain informed and up-to-date.

New Podcast Episode

What is Software-Defined Connectivity?

Related Articles