The Future of MEMs and IoT

The Future of MEMs and IoT

- Last Updated: December 2, 2024

Guest Author

- Last Updated: December 2, 2024

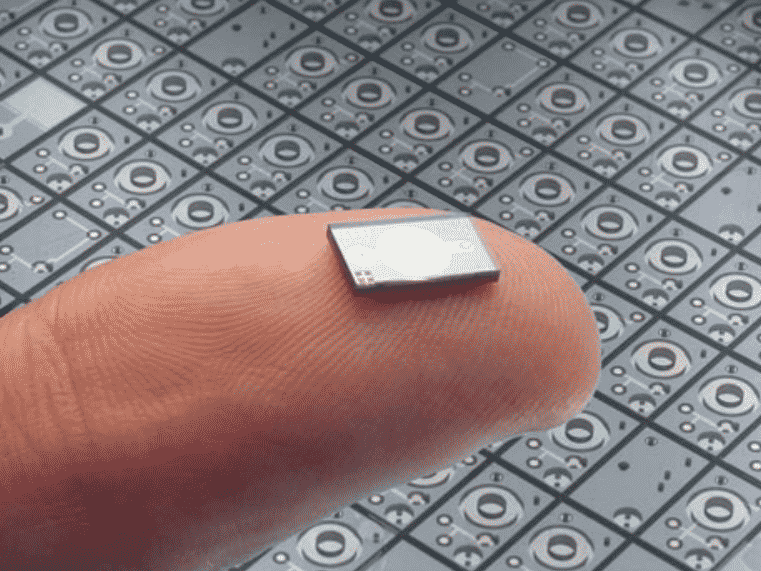

Have you ever wondered how many individual components make up your iPhone? There are accelerometers and gyroscopes to detect the movement of the phone. There are light sensors, temperature sensors, pressure sensors, and humidity sensors to measure the phone's environment. Then there are RFID, Bluetooth, and WiFi sensors for connectivity, as well as microphones and speakers for sound. Most of these components are Micro-Electrical-Mechanical Systems (MEMS). MEMS devices are machines between 1 micrometer and 1 millimeter in size.

Image Credit: Internet of Things Agenda

A MEMS Accelerometer in Action

Image Credit: Silicon Sensing

Small Forces, Big Impacts

MEMS devices often behave similarly to their larger counterparts with some notable differences. The sheer number of MEMS devices that can fit into a larger device like a smartphone is a key differentiator. A range of sensors and other MEMs devices can be packed into a pocket-sized smartphone.

MEMS are also significantly cheaper than their larger counterparts due to their manufacturing process. MEMS aren’t machined, but made with many of the same techniques used to make integrated circuits and semiconductors. The process overlap allows manufacturers to produce MEMS in batches without much need for new equipment.

One fascinating thing about MEMS is how small forces interact differently with these small devices than you might expect. For instance, you've seen the surface tension of water seemingly bevel water at the edge of your drinking glass. But did you know that in the context of certain kinds of MEMS, surface tension can actually cause water to pull itself through microscopic tubes?

[embed]https://www.youtube.com/watch?v=CNmk-SeM0ZI[/embed]

MEMS and IoT: A Shared Future?

The Internet of Things (IoT) can leverage several core functions and benefits of MEMS. MEMS devices can effectively meet the requirements of many IoT applications:

1: Low Power Consumption

IoT sensors and gateways are often required to be wireless and battery powered. Due to low per unit cost, it’s usually cheaper to replace the entire unit than to reinstall it with a new battery. Thus any reduction in power usage extends the life of the devices. Some MEMS face the same power requirements as their larger counterparts. Others take advantage of different forces in electromagnetism or fluid dynamics to reduce their power usage without sacrificing functionality—e.g., consider the case of surface tension transporting water through small pipes.

2: Small Form Factor

Users generally want IoT devices to be small and unobtrusive in office and home settings. MEMS are by definition unobtrusive. But beyond user needs, in some IoT applications, the device might need to be added to an existing machine—like a car—that has limited room for more hardware. In other cases like wearables and biomedical applications, small size is a critical requirement that must be met. Due to their small nature, MEMS meet and exceed these requirements.

3: Cost-Effectiveness

When deploying an IoT solution, scale is usually a major concern. For instance, when putting sensors to monitor weather and moisture levels on a farm field, there will need to be many devices seeded in each acre. Or consider an asset tracking solution in which there may be an extremely large (and variable) number of assets that need to be tracked. In other applications, such as shipping, a device may just be one-time use. MEMS are made through a process called photolithography, which makes it easy and cost effective to produce them in mass quantities.

As more devices and applications are added to IoT, MEMS will become more viable solutions. It's exciting to see how both of these technologies will grow and influence each other.

The Most Comprehensive IoT Newsletter for Enterprises

Showcasing the highest-quality content, resources, news, and insights from the world of the Internet of Things. Subscribe to remain informed and up-to-date.

New Podcast Episode

What is Software-Defined Connectivity?

Related Articles